Stucco vs Synthetic Stucco:

Which Exterior Finish is Best for Your Custom Home?

Stucco vs synthetic stucco, which material is better for your new custom home? This article will objectively lay out the pros and cons of each material.

What is Stucco?

Stucco is a type of exterior finish that is made from a mixture of cement, water, and sand.

It is applied as a wet paste to the surface of a building, and then allowed to dry and harden. Once it is dry, it forms a durable, weather-resistant layer that is resistant to wind, rain, and other elements.

Stucco is often used to finish the exterior of houses, apartments, commercial buildings, and other structures, and it is particularly popular in warm, dry climates.

It is known for its ability to provide a smooth, attractive finish that is easy to maintain and repair. We used synthetic stucco on our Halbert model contemporary home and you can see it here.

What is Synthetic Stucco?

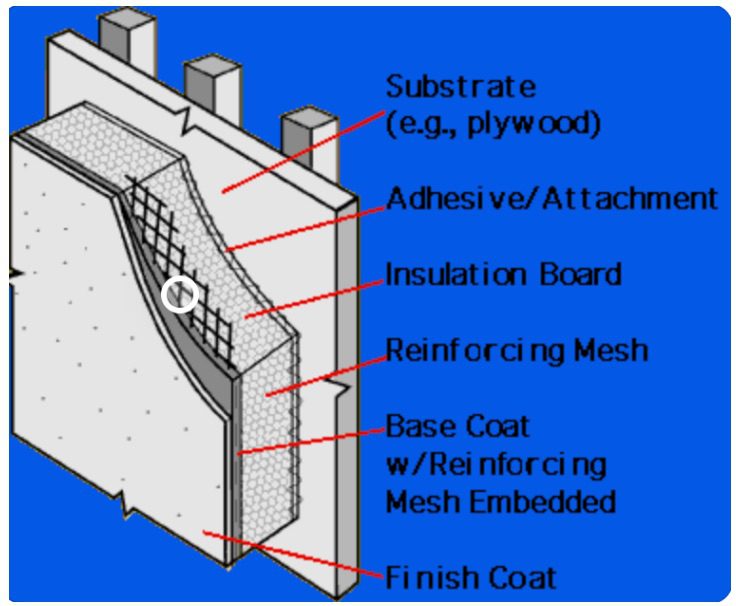

Synthetic stucco, also known as exterior insulation and finish systems (EIFS), is a type of exterior wall finish that is made from a combination of foam insulation, adhesive, and a polymer finish.

Both synthetic stucco and traditional stucco have their own unique characteristics and properties, and the right choice for you will depend on your specific needs and preferences.

EIFS is more flexible than traditional stucco and consists of a moisture barrier, foam insulation, cement basecoat, reinforcing fiberglass mesh and an acrylic finish. Synthetic stucco is 80% lighter than traditional hard-coat and relatively durable, due to containing fiberglass.

It was developed in the 1970s as a lightweight, energy-efficient alternative to traditional stucco

It is often compared to traditional stucco, which is made from a mixture of Portland cement, sand, and water, and is applied in layers over a wire mesh or metal lath.

Advantages of Synthetic Stucco

One reason that synthetic stucco may be considered better than traditional stucco is due to its energy-efficient properties.

Synthetic stucco is made from foam insulation, which helps to insulate the wall system and reduce heat loss.

This can result in lower energy bills and a more comfortable living environment, particularly in colder climates. Traditional stucco does not provide the same level of insulation, and may not be as effective at reducing heat loss.

Skilled crew installing insulation board

Another reason that synthetic stucco may be considered better than traditional stucco is due to its versatility and adaptability.

Synthetic stucco can be molded into a variety of shapes and textures, allowing for a wide range of design possibilities. It is also available in a range of colors and finishes, making it easy to match with other materials and create a cohesive look. We created decorative molded quoins on the corners of our Nevis model to add architectural accents.

Traditional stucco is not as versatile and may be limited in terms of the range of shapes and textures that can be achieved.

(Past) Problems With Synthetic Stucco

Synthetic stucco has been the subject of controversy due to its potential to trap water and moisture within the wall system. This has led to failures in some cases.

One of the main reasons that synthetic stucco failed in the past was due to issues with its installation and maintenance.

Synthetic stucco is applied in layers over a substrate, such as concrete or wood, and requires a series of steps to ensure that it is applied correctly and effectively.

If these steps are not followed, or if the synthetic stucco is not properly maintained, it can lead to problems such as water infiltration and damage to the wall system.

Another reason that synthetic stucco has failed in the past is due to issues with the materials used in its construction.

Some early versions of synthetic stucco used low-quality foam insulation or adhesives that were prone to degradation over time, leading to problems such as cracking and delamination.

In addition, some synthetic stucco systems did not include proper drainage or ventilation, leading to the accumulation of water and moisture within the wall system.

Synthetic Stucco Improvements

Over the years, efforts have been made to improve synthetic stucco and address these issues. Some of the steps that have been taken to improve synthetic stucco include:

- Improved installation practices: Synthetic stucco manufacturers and contractors have worked to improve installation practices and guidelines to ensure that the material is applied correctly and effectively. This includes the use of proper flashing and drainage systems, as well as proper sealing and ventilation to prevent water infiltration and damage.

- Improved materials: Synthetic stucco manufacturers have also worked to improve the materials used in the construction of the material, including the use of higher-quality foam insulation and adhesives that are more resistant to degradation over time.

- Testing and certification: Synthetic stucco manufacturers and contractors have also worked to improve the testing and certification of synthetic stucco products. Additionally, industry standards and guidelines have been developed to ensure that the material is of high quality and meets the necessary performance criteria.

Overall, while synthetic stucco has had its share of issues in the past, efforts have been made to improve the material and address the problems that have led to failures.

By following proper installation practices, using higher-quality materials, and ensuring the material is adequately tested and certified, synthetic stucco can be a reliable and effective option for exterior wall finishes.

You may also want to read this post comparing panelized framing vs stick framing a new home.